Unlock new possibilities in woodworking and fabrication with our MDF Cutting Machine CO2 Laser Machine. Designed for efficiency and precision, this advanced laser cutting solution is perfect for crafting intricate designs and high-quality finishes in MDF and other materials.

Key Features:

- High Precision Cutting: Achieve clean, precise cuts with our advanced CO2 laser technology, ideal for intricate patterns and detailed designs.

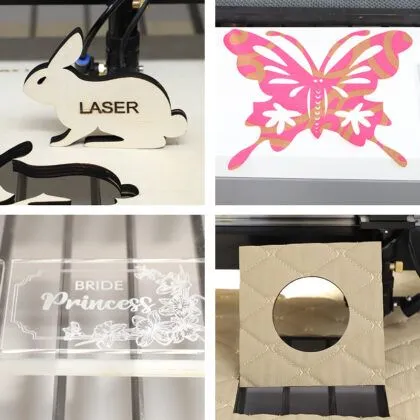

- Versatile Material Compatibility: Perfectly cuts MDF, plywood, acrylic, leather, and more, making it a versatile addition to your workshop.

- User-Friendly Interface: Equipped with an intuitive touchscreen control panel for easy operation, suitable for both beginners and experienced users.

- Fast Cutting Speed: Enhance your productivity with high-speed cutting capabilities, reducing production time without sacrificing quality.

- Safety First: Designed with multiple safety features, including an emergency stop button and automatic shut-off to ensure a secure working environment.

Ideal For:

- Furniture Makers

- Sign Makers

- Model Builders

- DIY Enthusiasts

- Custom Decorators

Technical Specifications for 3×4 MDF Laser Cutting Machine

Here are the comprehensive technical specifications for a 3×4 MDF Cutting Machine Co2 Laser Machine:

General Information

- Model: 3×4 Laser Cutting Machine

- Laser Type: CO2 Laser

Cutting Area

- Dimensions:

- Cutting Area: 900mm x 1300mm (approximately 35.4″ x 51.2″)

Laser Specifications

- Laser Power Options:

- 100W

- 130W

- 150W (customizable based on application)

- Laser Wavelength: 10.6 µm

Performance

- Max Cutting Speed: Up to 500mm/s (19.7 in/s)

- Max Engraving Speed: Up to 1000mm/s (39.4 in/s)

- Cutting Thickness:

- Dependent on material and power settings (typically up to 12mm for acrylic and fabric and 8mm for MDF)

- Precision: ±0.01mm

Material Compatibility

- Supported Materials:

- MDF

- Natural Fabrics: Cotton, Silk, Linen

- Synthetic Fabrics: Polyester, Nylon, Spandex

- Non-Woven Fabrics

- Leather, Wood, Acrylic, Paper, and other non-metal materials

Software and Interface

- Software Compatibility:

- Adobe Illustrator

- CorelDRAW

- AutoCAD

- Other vector graphic software

- Control Interface:

- 7-inch color touchscreen

- User-friendly operation with intuitive navigation

Cooling and Safety Features

- Cooling System:

- Water chiller – Closed-loop water cooling system for optimal temperature management

- Air Assist:

- Integrated air assist system to improve cut quality and minimize burning

- Safety Features:

- Emergency stop button

- Protective safety covers

- Automatic shut-off system to prevent overheating

Power Requirements

- Power Supply:

- AC 110V / 220V ± 10%

- Frequency: 50/60 Hz

Dimensions

- Overall Dimensions:

- Length: 1800mm (70.9″)

- Width: 1300mm (51.2″)

- Height: 1000mm (39.4″)

Weight

- Total Weight: Approximately 350kg

Optional Features

- Upgraded Laser Tubes: Higher wattage options for enhanced cutting capacity

- Rotary Attachment: For engraving cylindrical objects and items

- Fume Extraction System: To improve air quality and remove smoke and fumes

- Auto-Focus System: For enhanced cutting accuracy and convenience

- Conveyor Table Option: For high-volume production needs

Applications of MDF Laser Cutting Machine

Here are some common applications for an MDF Cutting Machine Co2 Laser Machine:

- Furniture Manufacturing:

- Cutting intricate designs for tables, chairs, cabinets, and shelves.

- Creating custom furniture pieces and components.

- Interior Design:

- Producing decorative wall panels and art installations.

- Designing customized moldings and trim.

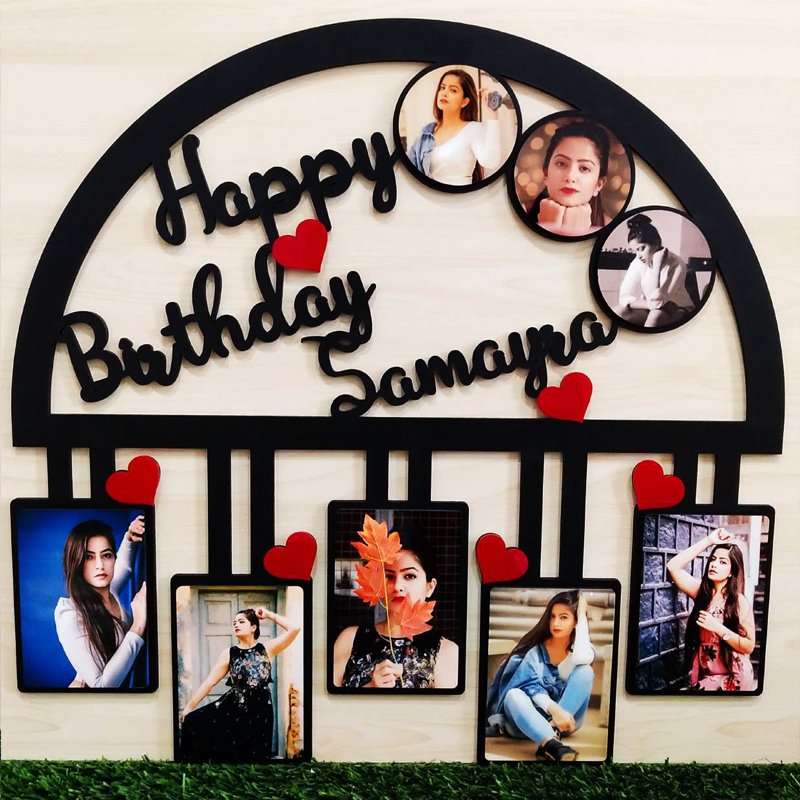

- Signage Production:

- Crafting intricate signs, logos, and branding materials.

- Engraving text and graphics onto MDF for promotional displays.

- Model Making:

- Creating precise models and prototypes for architectural projects.

- Fabricating detailed components for scale models.

- Craft and Hobby Projects:

- Making custom DIY projects, including home decor and gifts.

- Designing unique items for craft fairs and markets.

- Architectural Elements:

- Cutting and engraving decorative elements for doors, windows, and ceilings.

- Producing detailed architectural features like fretwork.

- Toys and Games:

- Manufacturing parts for educational toys and puzzles.

- Creating custom board games and playsets.

- Displays and Retail Fixtures:

- Designing point-of-purchase displays and stands.

- Creating shelving units and product displays.

- Customized Awards and Plaques:

- Engraving personalized trophies, awards, and recognition plaques.

- Producing commemorative items for events and ceremonies.

- Musical Instruments:

- Crafting components for instrument bodies and soundboards.

- Designing unique parts for custom instruments.

Benefits of Using an MDF Laser Cutting Machine

- Precision: Achieve highly accurate cuts and intricate designs.

- Speed: Fast processing times increase production efficiency.

- Flexibility: Easily switch between designs for custom projects.

- Minimal Waste: Efficient cutting reduces material scrap.

These applications highlight the versatility and efficiency of MDF laser cutting machines across various industries and creative fields.

Why Choose Us?

With a commitment to quality and customer satisfaction, our MDF Cutting Machine CO2 Laser Machine is engineered to elevate your woodworking projects. Benefit from our exceptional customer support and warranty options, ensuring you have the right tools for success.

Order the MDF Cutting Machine CO2 Laser Machine and bring your creative visions to life.

Conclusion

The MDF Laser Cutting Machine is engineered for high performance and versatility, making it an ideal solution for various industries, particularly in Signage, textiles and fabrication. For more information or to request a quote, please contact us!

Reviews

There are no reviews yet.